Growing demand for customised e-bike connectors

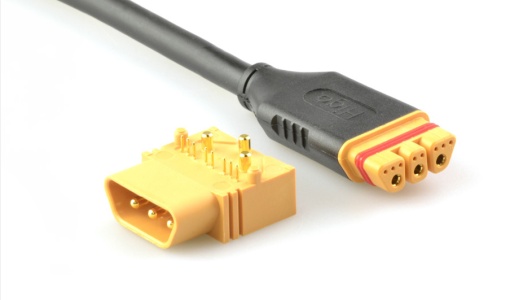

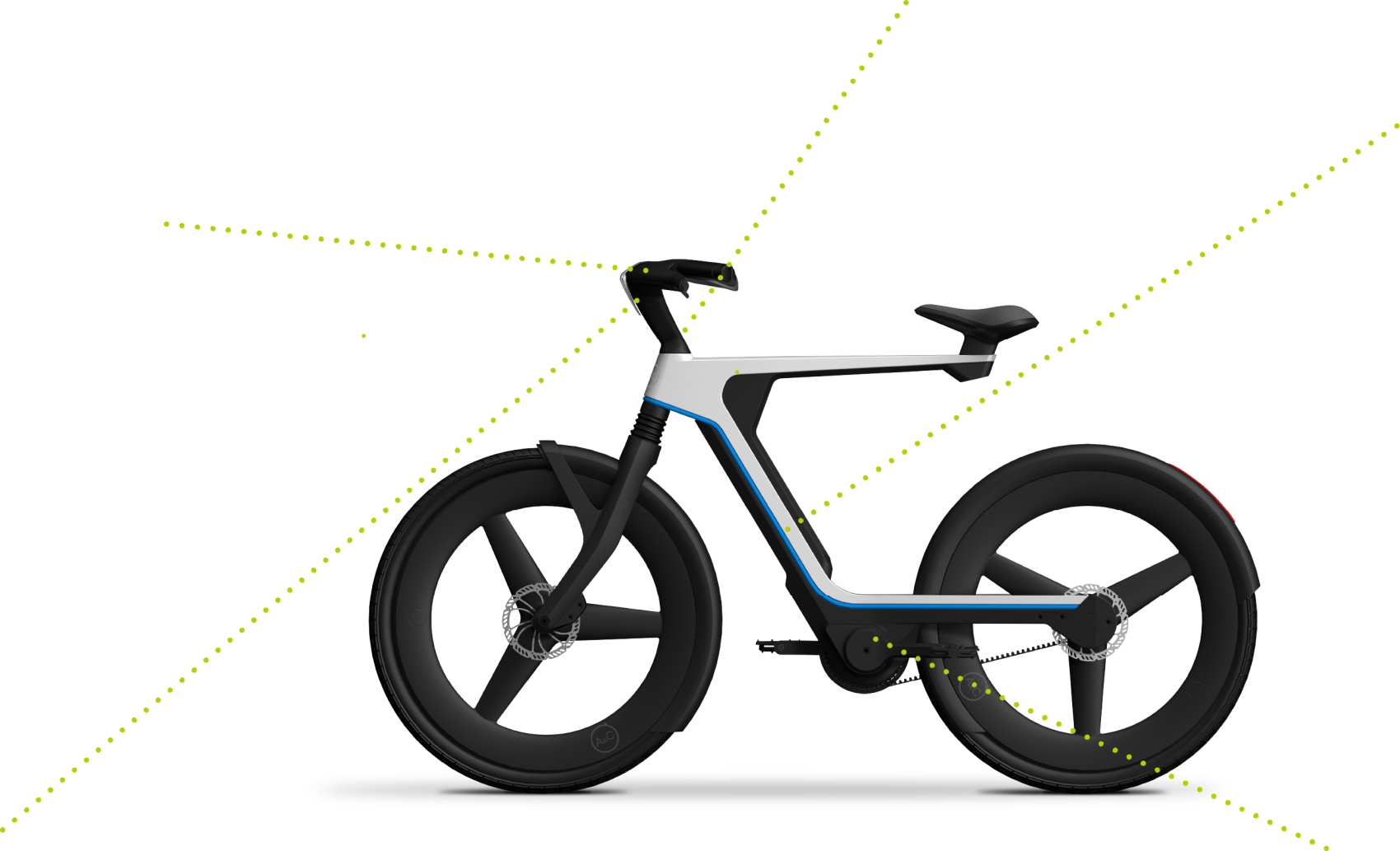

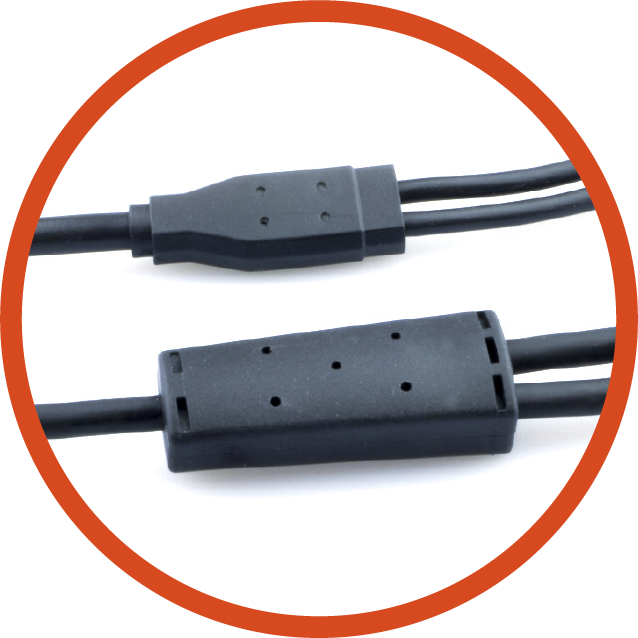

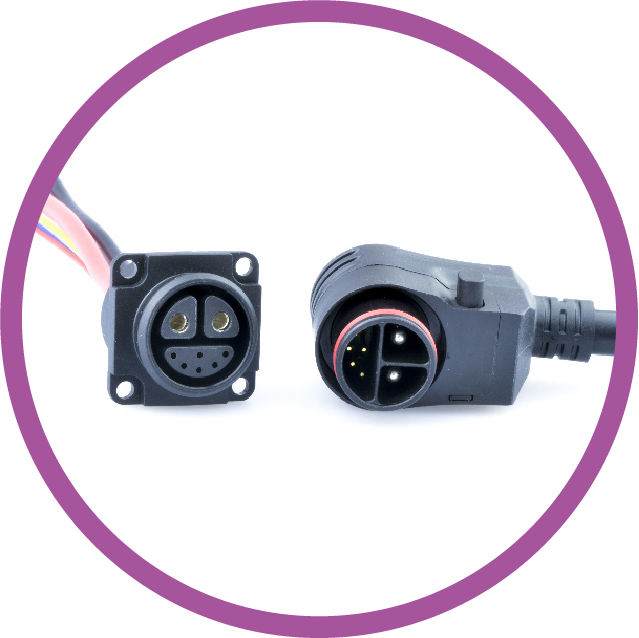

More and more e-mobility designs require more complicated, tailor made connections. Higo has the flexibility to fully design ebike connectors according to the specifications of each customer.

All of Higo's connector related processes are manufactured in-house, from the production of cables, tooling and the single-handedly turning of contacts until the complete assembly of connectors. This allows Higo to deliver customised ebike connectors according to its high-quality standards whilst keeping the production chain and hence the lead times as short as possible.

Higo’s expertise in customised connector design

Since 2008, R&D has been at the core of Higo’s success in designing high-performance e-bike connectors. Each year, 10% of the company’s turnover is reinvested in research and development, resulting in more than 60 registered patents to date.

Higo’s team of engineers combines creativity with technical know-how to translate customer-specific connector needs into practical, high-quality designs, tailored to any e-bike application. Whether it's compactness, waterproofing or easy installation, Higo delivers smart connector solutions that seamlessly integrate into modern e-mobility systems.

Beyond customised connectors:

discover the full Higo e-bike connector range