This is how we manage your project

Your ebike connector requirements

The type of E-bike application is always the starting point of our project. This project can consist of one or a combination of the follwing options: customised connector, cable assembly, splitter and cable harness. Depending on your needs, we will translate your application’s requirements to e-bike connector or cable harness specifications.

E-bike connector drawing

We will proceed with the set-up of a 3D concept drawing and step files. These will enable you to assess whether the e-bike connector or cable harness fits into your E-bike or E-bike system design.

E-bike connector prototype & samples

Once the 3D drawing of your e-bike connector or cable harness is approved, the next step is the production of a prototype and samples in order to start testing. Based on the results of your tests, the prototype will be further finalized until you are ready to start production.

E-bike connector production & quality check

The production team at Higo will be fully briefed with a final drawing according to ISO 9001 quality procedures. After production, outgoing quality & electrical tests are performed before shipment to A&C Solutions. At arrival at A&C Solutions’ warehouse in Belgium, the incoming e-bike connectors will be checked and compared with the initial drawing. After approval, the goods are ready for shipment to you.

European stock management for JIT delivery

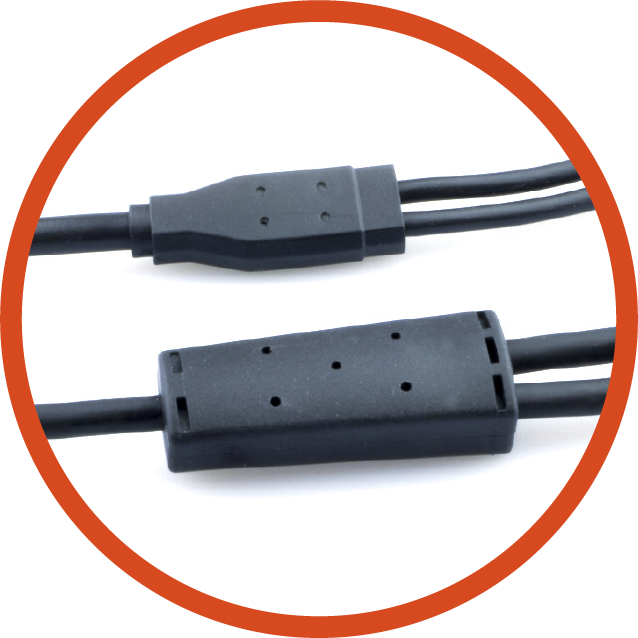

A&C Solutions manages your e-bike connector stock from our 1500m2 site in Belgium. We are able to ship recurring deliveries of your e-bike connectors and cable harnesses within 24 hours of your call-off. We also have a large stock of standard e-bike signal, battery and motor connectors directly available from our warehouse.

Higo customised cabling project with Nijland Cycling

Reduced installation & maintenance time with a custom e-bike wire harness

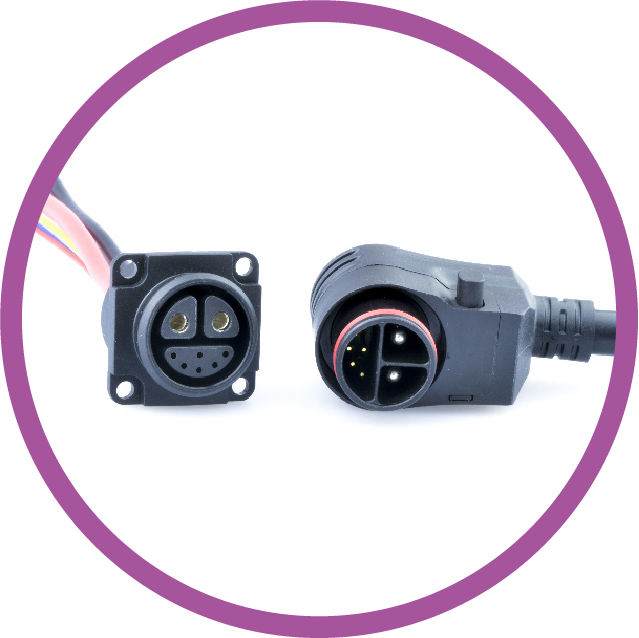

To simplify installation and reduce maintenance time, A&C Solutions developed a custom e-bike wire harness with Higo connectors for cargo bike manufacturer Nijland Cycling. Nijland was looking for a way to interconnect all electrical components—motor, display, battery and lighting—using one streamlined and efficient e-bike wiring harness.

By designing a tailored solution, A&C Solutions ensured that all systems could be powered through a quick and reliable wiring setup. The result? Faster assembly, fewer errors, and easier servicing. Discover in this video how this custom e-bike wire harness helped Nijland optimise production and performance.

Looking for a specific connector for your project?