E-bike wire harness expert

YOUR ONE-STOP-SHOP FOR FOR A CUSTOMISED E-BIKE HARNESS

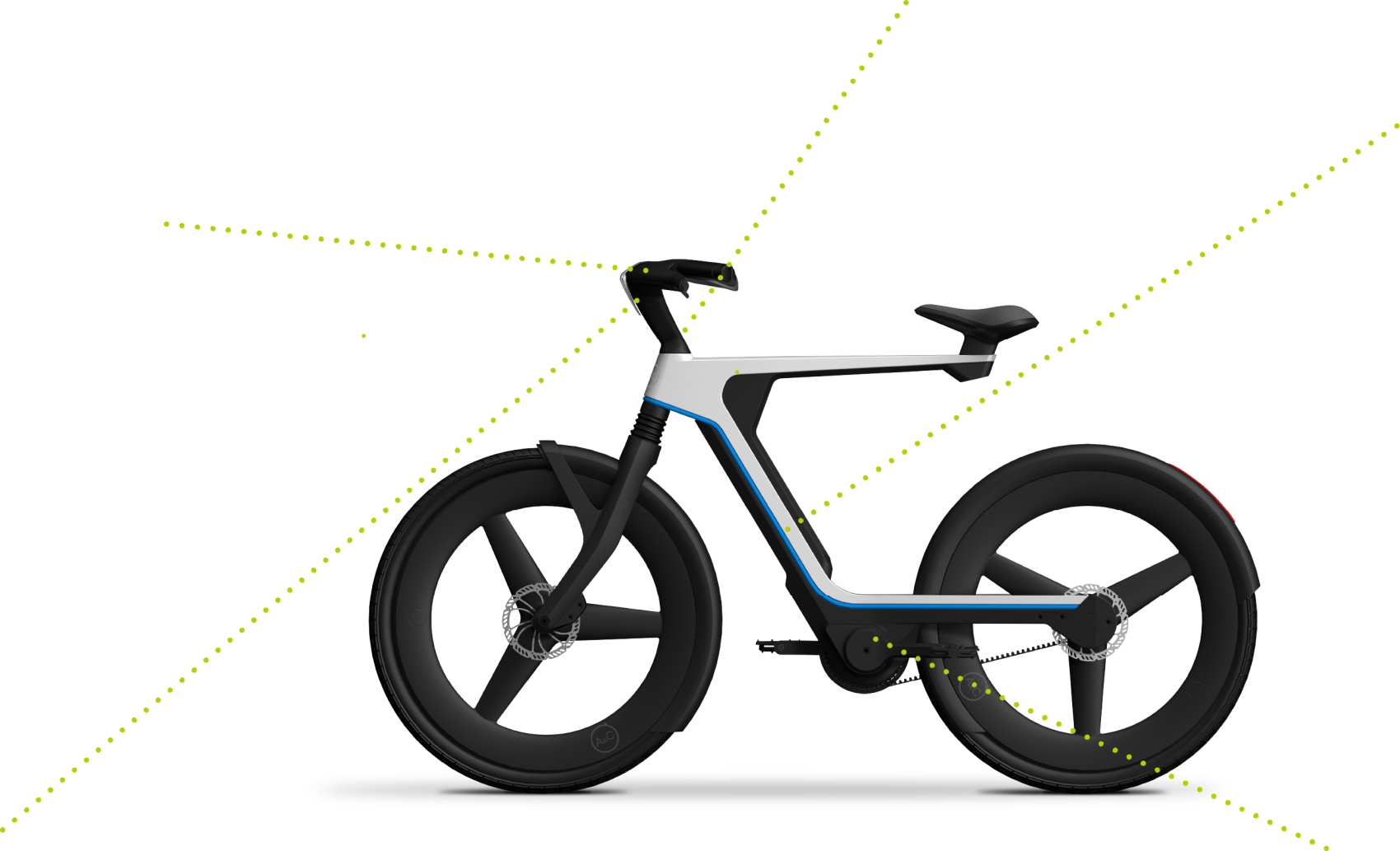

Customising your e-bike wire harness is one of our key strengths. At A&C Solutions, we have the stock, the experience and the production partner network to create any type of e-bike wiring harness at an attractive price. Whether you need small series or large volumes, we offer flexible, tailored solutions to match your needs.

Our e-bike wire harness solutions include:

- Special cable lengths

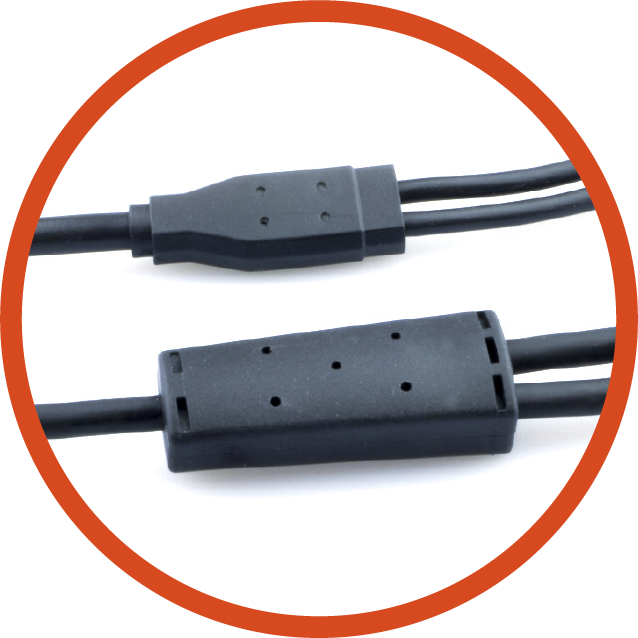

- Customised splitter cables

- USB cable integration

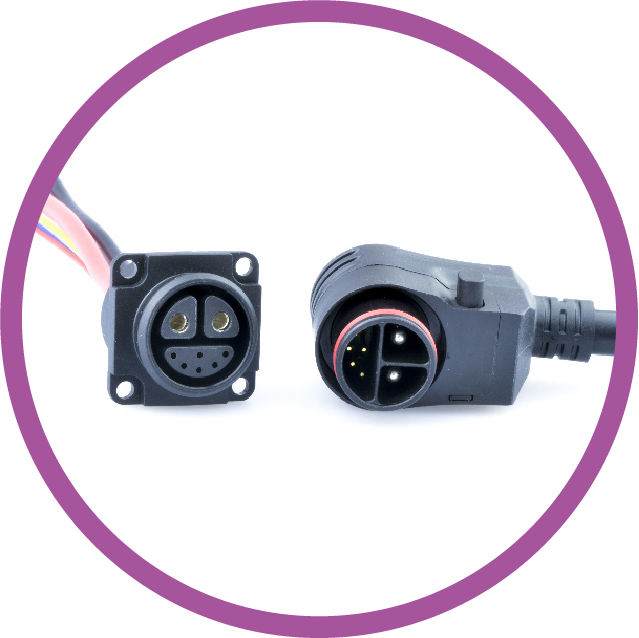

- Multi-brand connector combinations in one e-bike harness

Looking for a reliable e-bike wire harness partner? We’re here to support your next project.

E-bike wire harness project coming to life

Reduced installation & maintenance time with a custom e-bike wire harness

To simplify installation and reduce maintenance time, A&C Solutions developed a custom e-bike wire harness with Higo connectors for cargo bike manufacturer Nijland Cycling. Nijland was looking for a way to interconnect all electrical components—motor, display, battery and lighting—using one streamlined and efficient e-bike wiring harness.

By designing a tailored solution, A&C Solutions ensured that all systems could be powered through a quick and reliable wiring setup. The result? Faster assembly, fewer errors, and easier servicing. Discover in this video how this custom e-bike wire harness helped Nijland optimise production and performance.

E-bike wire harnesses – behind the scenes at Higo

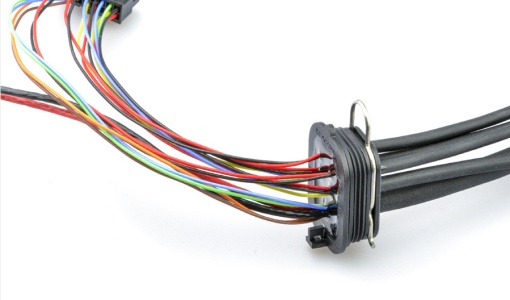

At leading e-bike connector brand Higo, the e-bike wire harness production process is built around quality, reliability and efficiency. From design to assembly, each harness is tailored to the bike’s specific electrical setup.

High-quality connectors are integrated through automated and semi-automated processes to ensure consistency and reduce errors. Every e-bike wire harness is thoroughly tested for watertightness, vibration resistance, and electrical safety.

Discover how Higo organises its e-bike wire harness production in this video.

Beyond e-bike wire harnesses:

discover the full Higo e-bike connector range